If you want to know the answer to the question “Do Stainless Steel Water Bottles Rust?”, then you are at the right place. The basic answer is no, these bottles don’t rust but this answer varies with different conditions as it can rust in some conditions. You have to read the whole article to get thorough information.

Introduction to above article

- Hey there, curious minds and hydration enthusiasts! We embark on a journey to get the answer to a common question that often comes to mind of those who love their stainless steel water bottles: Do they rust? It’s a concern. Ultimately, we rely on these soft, durable companions to keep us hydrated on the go.

- So, let’s dive into the details of stainless steel, exploring its composition, durability and the all-important question of corrosion resistance.

Decoding a stainless steel secret sauce

- First of all, what makes stainless steel a protective material for water bottles? There is magic in the composition, with chromium in particular.

- This unassuming element in our simple story is a superhero.

- Chromium reacts with oxygen to form a corrosion protector against stainless steel. Butare these weapons rustproof, CCanwe trust the quality of our stainless steel bottles?

Comparative Analysis: Stainless Steel vs. Plastic and Aluminum Bottles

- To truly appreciate stainless steel’s resilience, let’s compare it to two popular alternatives: plastic and aluminum.

- Plastic, although lightweight, tends to scratch and crack and has a short lifespan.

- Although aluminum is strong, it can be prone to corrosion and damage. Now, enter stainless steel, a heavyweight champion when it comes to durability. But what sets it apart from the rust field?

Corrosion resistance: A make-or-break factor

- The basic question emerges: Are stainless steel water bottles rusty? The simple answer is a resounding no – stainless steel water bottles are well insulated to resist corrosion.

- The chromium-rich alloy forms a protective oxide layer that acts as an impenetrable shield against corrosion.

Appropriate maintenance and repair instructions

- As we delve into the maintenance of stainless steel, we will explore cleaning methods, protective coatings, and storage recommendations.

- By adopting these practices, we not only extend the life of our water bottles but also strengthen their resistance to corrosion. Let’s discover the secrets of maintaining antique, plain metal vessels.

Beyond Corrosion: Health and Environmental Considerations

- Our quest doesn’t end with corrosion resistance. Stainless steel exceeds as an eco-friendly alternative, trumping plastic, which is recyclable and more environmentally friendly.

- When it comes to health, stainless steel is emerging as a safe bottle with no worries about harmful chemicals getting into our drinks.

Embarking on a journey of rust-free plumbing

- As we introduce you to the world of stainless steel bottles, from composition to corrosion resistance to a wide range of health and environmental considerations,.

- By the end of this journey, you will not only be well-informed about the durability of stainless steel but you will also be prepared to make the right choices for your plumbing needs.

Understanding Stainless Steel material

Stainless steel is a miracle in terms of material properties and is highly specified for its durability and resistance to corrosion. Let’s take a closer look at its characteristics and features that make it rust-proof.

Properties of stainless steel

- Stainless steel consists primarily of iron, with chromium being its main distinguishing feature.

- This alloy usually contains at least 10.5% chromium, which forms a protective oxide on the metal surface. This layer is incredibly thin, but it protects the metal from corrosion.

Properties of Chromium:

- Chromium is the unsung hero of stainless steel. It reacts with oxygen to form inert chromium oxide, which acts as a barrier, preventing further oxidation of the base metal.

List of alloy materials:

- Besides chromium, stainless steel contains other elements, such as

1. Nickel

2. Molybdenum

3. Manganese

- These additives contribute to strength, flexibility, and other desirable properties.

Water Resistance:

- One of the most valuable attributes of stainless steel is its corrosion resistance.

- Whether exposed to water, acids or extreme heat, stainless steel retains its integrity, making it ideal for many applications

Corrosion resistance of stainless steel

Silent film making:

- When stainless steel is exposed to oxygen, chromium atoms on its surface react to form a thin, invisible oxide layer.

- This inert film is self-healing, which means that if it is weakened or damaged, it automatically improves in the presence of oxygen.

Alloy Design

- The stainless steel alloy is carefully and precisely crafted to provide excellent corrosion resistance.

- Different applications may require different uses of chromium, nickel, and other alloys to enhance performance in specific areas.

Surface Finish:

- Treatments for fine metals, such as polishing or electroplating, can greatly improve the corrosion resistance of stainless steel.

- Smooth surfaces reduce the chances of cracks where water and dirt can accumulate, reducing the risk of damage.

Environmental Conditions:

- Although stainless steel is completely corrosion-resistant, its performance can be affected by extreme conditions.

- Factors such as high chloride concentrations, acidic environments, or the use of harsh chemicals may necessitate the use of specialized stainless steel or additional safety measures.

Appropriate Provisions:

- Even the most corrosion-resistant stainless steel requires care and maintenance to ensure its longevity.

- Regular cleanings and inspections can help identify and address any potential problems before they become serious.

Rusting Process

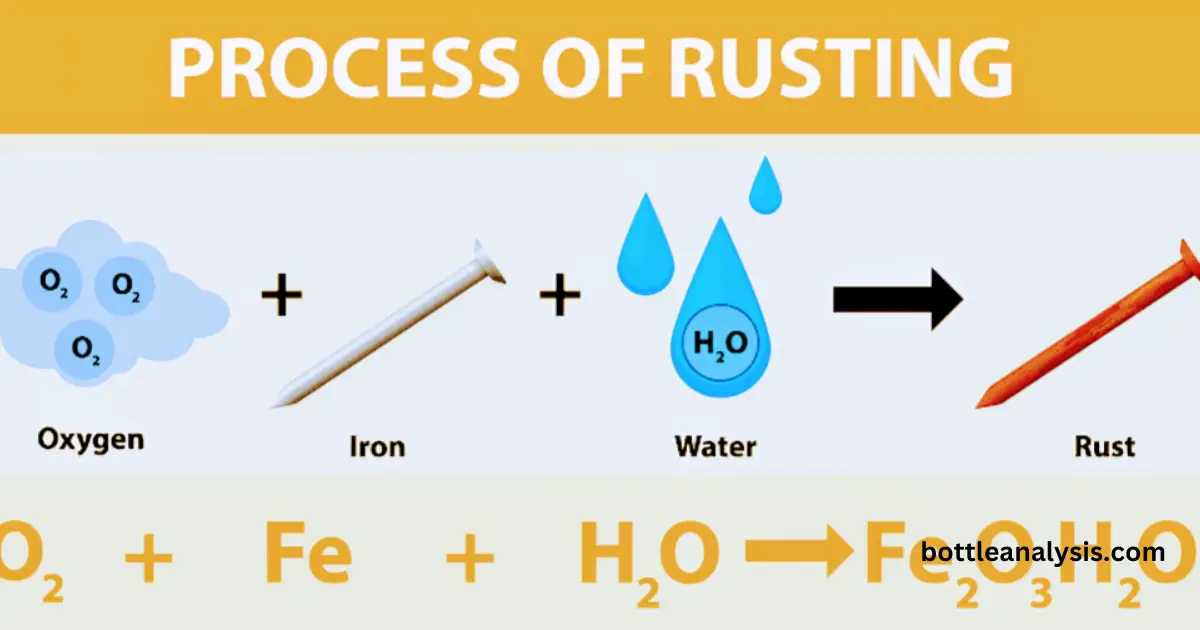

Corrosion is a natural process that occurs when metals and their alloys react with oxygen and water.

Let us dive into the complexities of corrosion and explore the open conditions for this corrosive change.

Description of corrosion formation

- Scientifically known as iron oxide, rust is a red coating that forms on the surface of iron, steel and other ferrous metals.

- Rust formation is a simple but interesting chemical process involving three important factors:

Iron (Fe):

- Common corrosive metals contain iron. When metal lies in the elements, it becomes susceptible to oxidation, and rusting begins.

Oxygen (O2):.

- Oxygen is key in a rusty game. It combines with iron atoms to form iron oxide, giving it the emphatic red-brown smoothness we normally associate with rust.

Water (H2O):

- Liquid or water, acts as a catalyst in the degradation equation. The presence of water makes it easier for oxygen to pass through the metal surface, speeding up the oxidation process.

Conditions of metal corrosion

Understanding the fertile conditions allows us to protect our beloved metal assets from corrosion. Here is an overview of the unwanted conditions:

Cold Water:

- High levels of moisture or direct contact with water create conditions favorable to rust. Water rapidly reacts with metals and oxygen, beginning as contamination.

Oxygen supply:

- A continuous supply of oxygen is essential for rust growth. Outdoors with lots of oxygen can accelerate corrosion, especially when there is pollution.

Salt content:

- In coastal or marine environments, the amount of salt in the air increases the potential for rust. Salt water, in particular, stabilizes sludge due to its electrostatic properties.

Acidic conditions:

- Acidic substances from industrial pollutants or natural sources can accelerate corrosion.

- The acids react with the metal, breaking down the protective oxide layer.

Overheating:

- Temperature fluctuations can affect the rate of rusting, especially in areas with severe winters or hot summers.

- The expansion and contraction of metal surfaces under temperature changes results in corrosion.

Airtight areas:

- A small amount of air can trap moisture on metal surfaces, creating an environment conducive to corrosion.

- Adequate ventilation is critical in maintaining stagnant conditions favorable for corrosion prevention

Factors Causing Stainless Steel Water Bottles Rust

Quality of stainless steel used in water bottle

- A non-rusting water bottle foundation depends on the type of stainless steel. Consider the following when choosing a stainless steel mate:.

Process Standards:

- Choose water bottles from reputable brands that adhere to strict manufacturing standards.

The effects of environment on the water bottle

Your stainless steel can is in a battle with environmental factors that can affect its surface integrity. Let’s examine what we need to keep in mind:

Increased humidity:

- In humid climates, moisture in the air can settle on your bag, creating an environment conducive to rust.

- Wipe your bag dry regularly, especially in wet conditions, to prevent rust from building up.

Regular cleaning:

- Follow a cleansing routine with mild soap and a soft brush to wash inside and out.

- This helps in removing the contaminants and ensuring that the chromium oxide coating remains intact.

Research:

- Check your water bottle periodically for signs of damage or corrosion. Addressing these issues early prevents them from moving into vulnerable areas.

Testing for Rust

Methods for detecting corrosion in stainless steel water bottles

Visual inspection:

- Take good care of your stainless steel water bottle. If you notice any discoloration, streaking, or a change in surface texture, it could be a sign of damage.

- Trust your eyes. They are your first line of defense.

Magnetic analysis:

- Grab a magnet (yes, like your refrigerator). Stainless steel is generally non-magnetic but loses this property in corroded areas.

- If the magnet sticks to a particular spot on your stainless steel bottle, it may be time to investigate further.

Paper Towel Test:

- Soak a paper towel in vinegar (mild acid) and press it on the affected area. If rust is present, the vinegar will react with it, creating a chemical reaction.

- A rusty answer means it’s time to address the issue.

General signs of corrosion formation

Color change:

- Beware of unexpected color changes in your stainless steel water bottle.

- Rust often begins as a subtle discoloration, signaling the start of a potentially damaging journey.

Scratches and pitting:

- Corrosion does not always appear as a major problem. Small spots or pits on the surface can be an early indicator.

- Pay close attention to these minor imperfections, and check your bag regularly.

Metallic smell or taste:

- Trust your instincts! If you notice a metallic smell or taste in your urine, it could be a sign of rust contamination.

Difficulties in Opening or Closing:

- If the caps or lids of your water bottle start sticking or become hard to open and close, it might be a sign of rust.

Preventive Measures

Let’s dive into some practical tips and tricks to keep your favorite water bottle rust-free and shiny.

Proper maintenance procedures to prevent corrosion

Mild soap and warm water:

- When it comes to cleaning your stainless steel water bottle, stick to mild soap and warm water. Harsh chemicals can damage the protective layer, opening the way for corrosion.

- A little TLC goes a long way!

Soft cleaning brush:

- Choose a soft brush to gently scrub the inside and outside.

- This helps eliminate any unabraded residue that could compromise the corrosion protection of the stainless steel.

Daily cleaning routine:

- Make water bottle washing a regular routine. When you will wash the bottle, there will be less chance of dust.

- A few minutes of self-care can save you from rusty headaches in the future.

Protective coating or treatment of stainless steel

Wax or oil:

- Consider applying food-grade wax or oil to your stainless steel water bottle for added protection.

- This will act as a shield against harsh conditions, which will add extra protection.

Titles: Stainless Steel Cleaner:

- Invest in specialized stainless steel cleaners. These cleaners are designed to preserve the integrity of the metal, effectively removing stubborn stains or residues that can cause corrosion

Conservation recommendations to minimize the risk of rusting

Store in a dry, airy place:

- Once water bottle will be cleaned, we should make sure your water bottle is dry before storing it.

- Choose well-ventilated areas to eliminate trapped water, reducing the risk of rust.

Avoid prolonged exposure to water:

- If you are not going to use your stainless steel water bottle for a long time, avoid leaving water in it. Drain thoroughly, and store in a cool, dry place.

- This prevents soft water from becoming a source of rust.

Psychology:.

- Avoid surfaces or environments exposed to harsh conditions, extreme temperatures, or corrosive agents, which may compromise its corrosion resistance.

Comparisons with Other Materials

Let’s set up a comparison journey to help you make important choices in your day-to-day challenges.Today we’re focusing on stainless steel, differentiating between plastic and aluminum, emphasizing corrosion resistance, and examining health and environmental impacts.

| Properties | Steel Stainless Steel Bottle | Plastic Bottle | Aluminium Bottle |

| Sustainability | Known for its durability, stainless steel outshines plastic and aluminum in terms of durability. It withstands impact, temperature changes and damage during everyday use. | It shrinks, cracks and deteriorates over time | While hard, it can bend and corrode |

| Corrosion resistance as a selection criterion | Choosing stainless steel provides better corrosion resistance. The chromium content acts as a protective coating, making it reliable for products such as water bottles containing water. | Plastic materials are naturally resistant to rust, but over time they deteriorate and lose their design, affecting their performance. | While aluminum is generally safe, some studies point to possible health risks associated with excessive consumption. |

| Longevity | It lasts longer compared to plastic and aluminum, making it a more sustainable option | It is Prone to wear and may need frequent replacement | It can wear out over time, affecting its longevity |

| Environmental friendliness | It is Highly recyclable and often made from recycled materials | It is notoriously difficult to recycle, posing environmental problems | It is recyclable but takes a lot of energy to produce |

Conclusion

In the area of stainless steel water bottles and corrosion, the answer is no.

- Stainless steel water bottles are designed to resist corrosion due to the presence of chromium, which provides corrosion protection.

- This durable material outshines other options such as plastic and aluminum in terms of durability longevity, durability, and environmental impact.

- The health and environmentally-conscious consumer can rely on stainless steel for safe, durable, and rust-free water.

- So rest assured that your stainless steel water bottle is not only a reliable companion, but also a solid protection against unwanted rust intrusion. Cheers to a worry-free sustainable hydration journey with your rust-resistant stainless steel friend!